Already Have a SteepSlope Scaffold Kit?

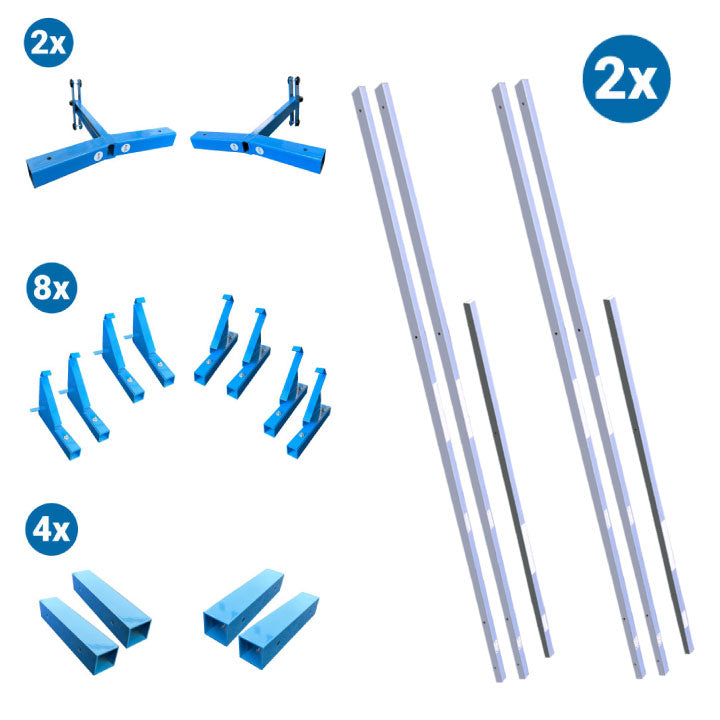

Shop SteepSlope Scaffold Parts & Add-Ons

Increase Your Job Speed & Revenue.

The SteepSlope Scaffold allows laborers to cut job times by up to 50%. This allows them to take more jobs and make more money.

Built for Roof Pitches Between 8/12 through 14/12

Works on Metal, Slate, Tile, & Asphalt Roof Materials

Developed, Tested, & Manufactured in Philadelphia, PA

Made to Keep Your Operation Compliant With OSHA Standards

The Steep Roof Swiss-Army Knife

What sets the SteepSlope Scaffold apart from anything else on the market is it's incredible versatility. You're not a one-trick pony, and your tools shouldn't be, either.

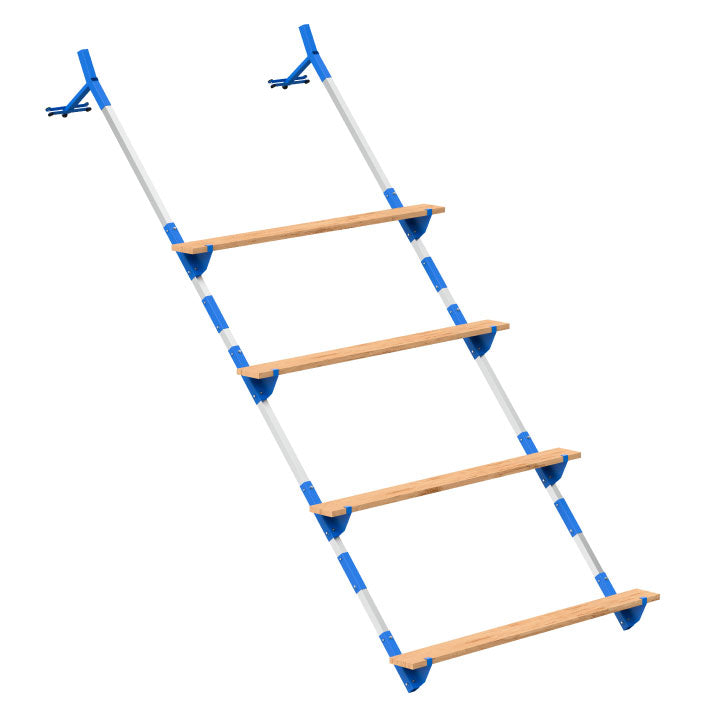

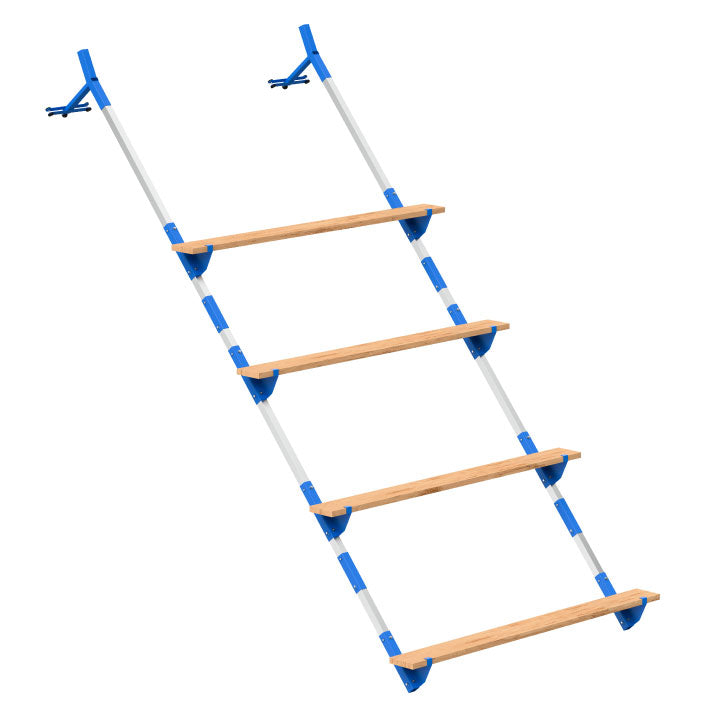

1 Rail: Steep Slope Assist

Use the wheels on the end of the scaffold's bracket to roll it up the roof and hang it over the ridge. Now you can easily climb up. It's the perfect tool for roof inspectors, or the first man up or last man down on a job.

2 Rails: Working Platform

Simply add 2x10s to create a sturdy platform to work off of--and even store your tools & materials. It's perfect for quick repairs, re-roofing jobs, skylight/solar installs, and more.

Setting Up the SteepSlope Scaffold

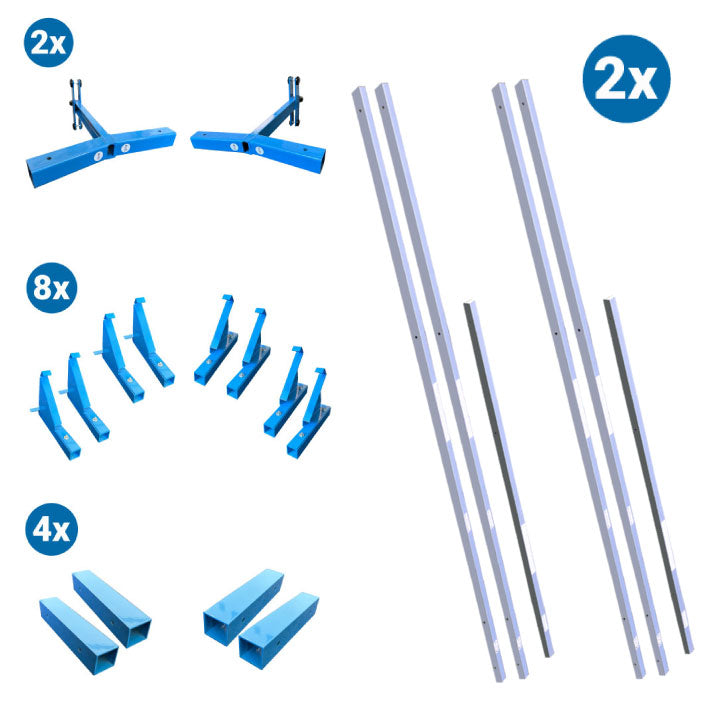

Attach the Brackets

The SteepSlope Scaffold's brackets simply attach by use of quick-connect pins. Pull the pin, slide the bracket onto the rail, and re-insert the pin. Boom--your SteepSlope Scaffold is assembled.

Roll it up to the Ridge

Use the wheels on the back of the ridge mount bracket to slide it up the roof and over the ridge. This will allow you to set it before even climbing up the roof.

Fasten it to the Ridge

Instead of harming your customer's property by nailing into 30-60 shingles, with the SteepSlope Scaffold, you just need one nail per rail. Fasten the ridge bracket so that their's about 1.5" between the rail/roofing structure.

Simple.

Easily Shingle Under Rails

The beauty of the SteepSlope Scaffold is that it's a free-floating system. This allows you to slide materials (and remove them) under the rails with ease.

Safe.

Easy Movement

Walking on steep roofs is a pain in the @$$. But with the SteepSlope Scaffold, you now have a sturdy area to easily move around the roof.

Scaffolding for Any Roofing Material

Asphalt

Metal

Slate

SteepSlope Scaffold Customer Reviews

This should be standard equipment for every roofing crew. It doesn't cost much, it's a quality made product and really helps make our roofing jobs safer and faster.

Jim R.

Took only 15 minutes to make a repair. Using old style brackets would have taken hours. Didn't have to nail into the roof which would've caused more repair work

Roberto A.

Great price on the equipment I needed. Everything was shipped correctly and instructions are easy to follow. Very fast shipping!

Cole B.

It's like the 21st century version of the chicken ladder. Really great idea.

Rich S.

Have any questions for our team?

- Al seleccionar una opción, se actualiza toda la página.

- Se abre en una nueva ventana.